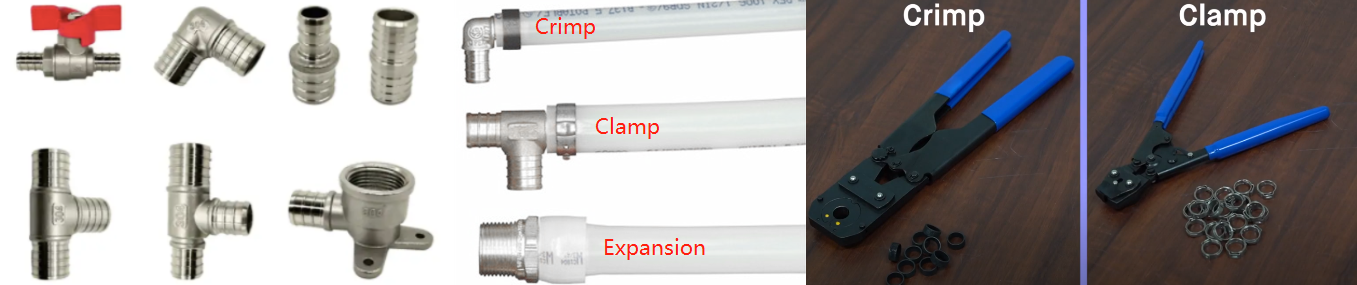

There are different connection methods for PEX that can be produced with a pressed stainless steel sleeve or a PEX crimping ring. A stainless steel PEX ferrule joint compresses the hoses and inserts a fitting between the two points to secure the hoses.

The stainless steel PEX crimping sleeve connection is inserted at the end of the hose and the crimping fitting is inserted into the connection to lock the connection. A special tool or crimp ring is required to connect the hose to the push-fit or fitting connection. The connection can be made with either a PEX pressing tool or a Pex pressing tool, as recommended by the manufacturer.

Some manufacturers use O-rings for their metal fittings made of sealed hoses according to ASTM 2434 standard. Stainless steel crimp and pex fittings can be used for almost any application. Crimp fittings are preferred for many applications because they are readily available and affordable.

High-quality stainless steel crimp PEX fittings are an excellent choice for residential, commercial and specialized sanitation applications, from large condominiums and urban sanitary facilities to water systems for groundwater supply in rural areas. Their use is not limited to sanitary installations, but is also used in special applications from hydronic heating to the maple syrup industry. Stainless steel PEX fittings are available with contra-angle adapter coupling, T-fitting, ball valve, polybutylene PEX transition coupling.

To make a PEX connection, use a crimp ring or stainless steel clamp and first cut the PEX pipe square. The distance between the edges of the PEX pipe varies depending on the material type and manufacturer. Push the crimp rings into position where the Pex fittings (metal and plastic) overlap.

If you are looking for a fast and more secure connection that will stand the test of time, crimp tools are your better option. But if you want more flexibility without working more, go for PEX clamps.

Post time: Jun-25-2021